Name Behind the Name: Bruce Jackson – Apogee, Jands, Lake Technology

Whether it’s mixing Elvis, Bruce Springsteen or Barbra Striesand live, starting Apogee out of a garage or masterminding leading-edge live sound DSP processor development, Bruce Jackson has a tale or two to tell. Andy Stewart listens.

Not too many people in the world have packed more into their careers than Bruce Jackson. Bruce is one of those people who seems to have had so many experiences in his life that when you do a rough calculation on how old he must be, the number would seem to indicate that he’s been dead for several decades. In actual fact, Bruce is scarcely in his 50s and is as passionate, open-minded and motivated by advancements in audio technology today as he has ever been. From building his own radio station, establishing Jands, getting his pilot’s licence and mixing Elvis Presley live, all before the ripe old age of 22, Bruce Jackson hasn’t exactly been sitting around twiddling his thumbs.

Names behind Bruce’s name include several familiar audio brands such as the aforementioned Jands (an acronym of Jackson and Storey), Apogee Electronics, and these days, Lake Technology. If we were to include other names for which Bruce has designed equipment, toured the world as front of house engineer or simply had a guiding hand in supporting, the list of names would trail off the page, down the hall and out the door. The abridged version of this rollcall includes Clair Brothers, Fairlight, ProTools, Elvis Presley, Bruce Springsteen, Barbra Striesand, Dianna Ross, Johnny Cash, Fleetwood Mac, Stevie Wonder, Rod Stewart and the Faces, Barry White, Jefferson Airplane and Ozzy Ozborne… just to name a few.

As some may have surmised from this extraordinary (partial) CV, Bruce has spent a decent chunk of his adult life in the United States. It was in that country that his considerable talent for live engineering and penchant for electronic wizardry was able to fully express itself, and where he set up his world-renown pro audio company, Apogee Electronics in a garage in Santa Monica.

Bruce Jackson has always worked at the cutting edge of technological advancement, but unlike many others in the audio industry, his youthful perspective has never waned. As most people gain experience and become established in a field of expertise a strange and ironic process begins to engulf them. Their knowledge and skill – the very thing that defines them as experts – tends to date them, and the learning of new ‘tricks’ becomes harder and harder until eventually they’re outmoded. No so with Bruce. He’s as cutting edge now as he has ever been. Ideas are in plentiful supply and there is always a new and innovative audio solution just around the corner. When I caught up with Bruce at Lake Technology’s headquarters in Sydney recently, he greeted me at the door resplendent in blue denim jeans, a striped shirt and white running shoes. Cutting edge in audio he may me, a fashion consultant he is not.

Bruce Jackson: Yeah, well, I’m always getting criticised around here for my fashion sense. But it wouldn’t matter what I wore, these younger guys at Lake are determined to act as a constant reminder that I’m the old guy around here. I don’t feel like an old guy until I look in the mirror, but I can’t be blamed for that, surely!

THE WONDER YEARS

Andy Stewart: If we can take a few steps back in time, do you remember how you first became ensnared in the audio industry?

BJ: I was pretty young when I first started meddling with audio equipment. As a kid I just enjoyed electronics. I had a little lab under the house in Point Piper, which coincidentally, was right next door to where Kim Ryrie [co-founder of Fairlight] had a setup under his grandmother’s house. Kim, in fact, named his company after the hydrofoil that went past us every day – The Fairlight. One day when Kim was searching for a company name, the Fairlight went by, and the rest is history.

When we were about 17, Phil Storey and I started Jands out of our respective bedrooms and the Altona, Point Piper address was the registered office. I lived in the boatshed next to the pool and had my little setup down there by the water. Not a bad spot actually – in fact, last time the house was sold it officially became the most expensive house in Australia! It was a spectacular place to grow up, that’s for sure.

AS: What was Jands all about at its inception?

BJ: Jands was just two eager electronics enthusiasts – myself and Phil – who built whatever the hell they felt like. Well before the name Jands even existed we were building TV sets out of radar tubes, guitar amps and speaker columns out of second-hand bit and pieces – that sort of thing. I will always remember how exciting it was building something with my own hands and hearing this great sound coming out of it – or at least I thought it was great sound at the time. Those early successes were what inspired us.

Around that time, Phil, myself and a bunch of other friends at Vaucluse Boys High School decided to build a little radio station out of all these old disposal parts. We used to broadcast illegally after school, up the end of the AM band. The antenna for our broadcast ran from one end of the school to the other, which consequently made it really, really efficient – too efficient as it turned out. We thought we were broadcasting across the neighbourhood when, in fact, we were actually transmitting right across Sydney. But eventually the PMG van triangulated in on us, busted us and shut us down. But it was fun while it lasted.

Later, when Phil and I went on to university together we teamed up with Roger Foley who had a rental company called LSD Fog and we started building stuff for him. Pretty soon though we realised that we could do this ourselves, and the real Jands was born. We moved from our very exotic location in Point Piper to Rose Bay where we had an office above a florist shop. We designed and built everything there: lighting rigs, amplifiers, dimmers, PAs… it was totally hands-on. We designed the printed circuit boards, etched them, drilled them and put the components in. The next thing we knew Jands started to become really successful and the rental thing started to pay for us to design new stuff, and it just went from success to success. But we were young and eventually we got the shits with each other and sold out to four guys who still own the company today. Phil went and worked for them and I took off overseas.

AS: Why were you headed in that direction?

BJ: Around that time (1969 I think) I met Roy Clair from Clair Brothers during a Australian tour of Blood, Sweat and Tears, which was the first time we’d seen a really big, high quality PA in Australia. I remember the gig was at Randwick racecourse, and I knew a way in over the back fence. So myself and Russell Dalliston (who went on to become chief engineer at Channel Nine) snuck in and saw the show. We were so keen to know more about the PA that we just went up and spoke to Roy and asked him a whole stack of questions about it. The short version of this story is that I ended up becoming friends with Roy, and soon after that, did a tour with Johnny Cash as Front of House engineer using the same PA.

Before I knew it I was over in The States visiting the Clair Brothers facility in Pennsylvania, which, at that time, consisted of a small barn outside of Lititz – the Pennsylvania Dutch area where the Amish live. Clair Brothers was a regional PA company back then that did shows in east coast areas – before the days when tours went with one sound company across the whole country. I stayed and worked for Clair Brothers for several years, and while I was there I designed (along with Ron Borthwick) the foldout console, which I subsequently used regularly on tour with Bruce Springsteen during the 1980s. We built 10 of these consoles and they were the Clair mainstay for a dozen years (see pic left). It was the first live console to use parametric EQ. My parametric EQ also became the first parametric EQ in hi-fi as an SAE [a US audio brand] product.

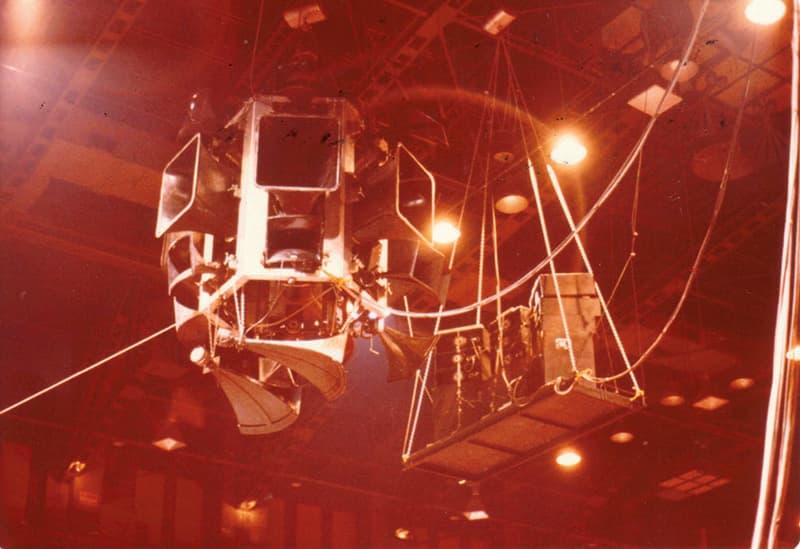

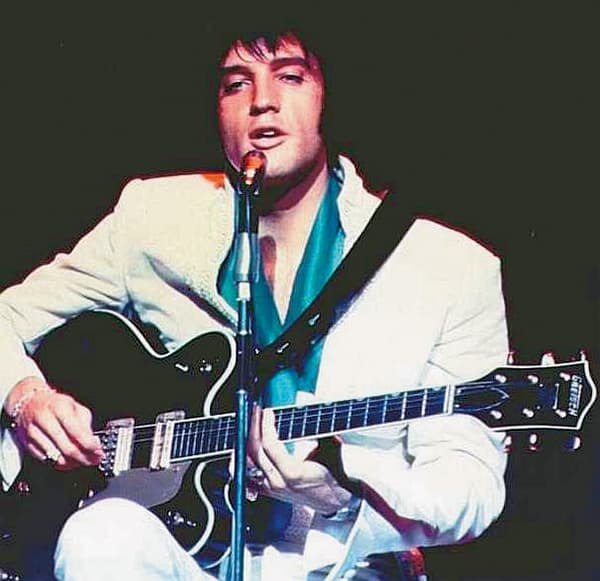

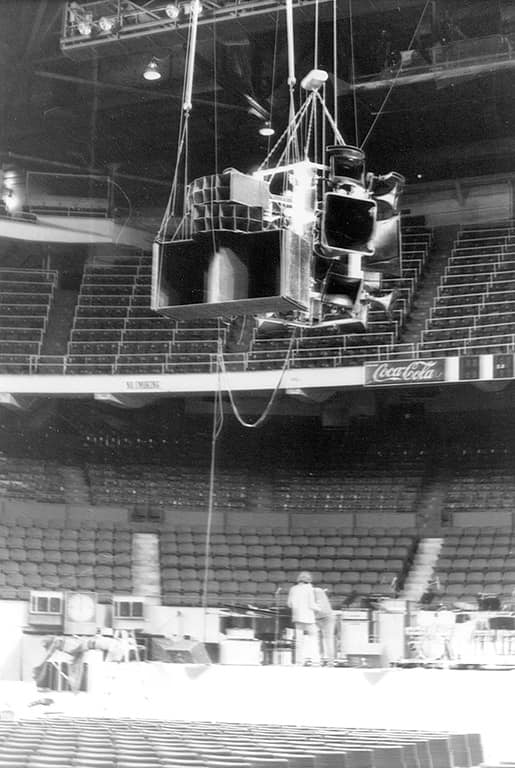

It was during my tenure at Clair Brothers that Elvis Presley started touring again. Initially many different sound companies did Elvis’ sound on a regional basis. Fortunately (for me, as it turned out) most had problems with hanging the sound and logistics, and as a result Clair Brothers got the gig. So before I knew it I’d become Elvis’ touring engineer. It was an exciting time, and a period of great innovation. It was the first time a live show had hung the sound system (although the Ice Show had previously hung a very basic rig) – not for sound quality reasons, which is why they do it now, but so The Colonel [Elvis’ manager] could sell every seat in the house. We were the first to hang the PA from chain hoists mounted upside down; a standard practise nowadays. The PAs were much smaller then of course, but I still don’t know how we ever got away with it. It was all evolving and real seat-of-the-pants stuff.

AS: How long did you work with Elvis for?

BJ: I mixed and ran the sound for Elvis for six years. I think I was about 21 when I started with him.

AS: Most young engineers are still doing their SAE degree at that stage of their career! Did it seem like a big deal at the time?

BJ: Nup. I had no idea. It was just a lot of work; you’re tired all the time, working strange hours and constantly travelling to the next destination. I did hundreds and hundreds of shows with Elvis across mainland United States and Hawaii. We would travel around in four or five different jet planes: Elvis had his own plane; the band had theirs; The Colonel had his plane; and concessions and crew yet another. Finally, the manager of RCA would travel ahead of us in his Learjet. At our hotels, there was a similar setup. Elvis would have his own floor, as would The Colonel and everyone else had their own rooms. As you might imagine, this separateness wasn’t exactly conducive to keeping the group together; there wasn’t a lot of chit chat about preparations for the next gig or anything like that. Elvis was kept very isolated.

It was an amazing time, though, especially when we travelled down south where everyone just loved Elvis like family. We’d get treated like royalty down there – police escorts, all that stuff. I remember one time where I mentioned to the police captain in Alexandria, Louisiana, that I was a self-confessed aviation nut and the next day he sent a sergeant over to pick me up and fly me in the police helicopter all the way down the Mississippi to Baton Rouge. Most performers don’t get treated like that let alone the engineer. They just loved Elvis so much they’d fall over themselves to please us in any way they could.

AS: Did Elvis play an active role in the setup at all?

BJ: No. That kind of interaction didn’t really exist in those early days. There was no touring sound company or production values as such. For instance, the only lights we used were follow spots. There wasn’t even a sound check, and foldback was mixed from the house console. It was chaotic really, by today’s standards. You just had to do the best you could, and hopefully you’d be lucky enough to get through the night. Some nights would work well and others would be a total train wreck. After a while it became self-evident that Elvis’ ability to hear himself on stage was crucial to the show’s success, so I pushed for the establishment of an engineering role that would involve a stage PA and an engineer to manage it.

AS: Does this mean we have Bruce Jackson to thank for inventing the role of foldback engineer as we know it today?

BJ: No, not really. It was more that its time had just come. People had been putting monitors around the place for years before that. But it had become increasingly obvious to me that making Elvis comfortable on stage was a specific task all its own, not just part of front of house duties. But it took time to convince people of that.

AS: Did you take on the role of foldback engineer when the management finally acquiesced?

BJ: For a time there I was doing both, and a guy called Charlie (who was Elvis’ army buddy, acoustic guitarist and set list caller) would communicate with me via headset and send me messages like ‘turn this up’ or ‘turn that down’ – this was before the days of foldback consoles. But yes, eventually I became ‘foldback’ engineer on the tour because Elvis wanted me to be right there next to him and that’s all he really cared about. He wanted me to watch him all the time and would look for approval when he had done unusually well. I would sit beside the stage with Elvis’ girlfriend (whoever that happened to be at the time) and record producer, Felton Jarvis. But because there was no sound check, Elvis would walk out on stage and have absolutely no idea what to expect. It was very stressful for all of us. I remember a number of times he stopped the show and had me come up and stand right next to him while he sang with 20,000 people watching. Eventually we all agreed that this approach was insane and from that point, Felton and I would meet before every show and make some attempt at preparations. But there was still no concept of sound check… Elvis never did a check of his foldback… ever.

AS: Did anyone ever rehearse?

BJ: Sort of. I would fly down from Pennsylvania to Memphis in my little plane (which is about 800 miles), with the back full of mic stands, leads, monitors and bits and pieces, and be met on the tarmac by Elvis’ bodyguards. They’d unload the gear out of the plane and we’d drive back to Graceland where I’d set up in the racquetball court. But often that’s as far as rehearsal would progress. Generally, the band and I would just sit around in the Jungle Room watching TV, waiting for Elvis to come downstairs. We’d watch all the food going upstairs to his room, but he’d never show. That was the extent of rehearsal most of the time. Then we’d go off on tour…

AS: That must have made some of the shows quite ‘interesting’?

BJ: On tour Elvis wouldn’t talk to the band off stage, but he was very sensitive to what was going on during the shows themselves. It would only take a small mistake for Elvis to give you the sideways glance over the shoulder. If you got one of those you knew that you’d better not make that mistake again. He was very sensitive and tuned in, but totally isolated by his guys in the end. In a strange kind of way that made him very freeform too, and no two gigs were ever the same. I remember one night he was doing a show in front of thousands of people and before I knew it he’d broken into a performance of Happy Birthday… for me: “Ladies and Gentlemen, it’s my sound engineer Bruce Jackson’s birthday today, so without further ado… happy birthday to you…” which was amazing, and very embarrassing.

FAIR FLIGHT

AS: What role did you play in Fairlight’s development?

BJ: When Kim [Ryrie] and Peter [Vogel], who started Fairlight, finally got the sampler up and running, their main problem was that they didn’t really have any contacts in the international music business. So I helped them out by setting up distribution in the US, where I was friends with a whole bunch of musicians like Rick Wakeman and Tony Bonjovi (who built the Power Station in New York City). Tony was kind enough to let me set it up in an unfinished studio he had [John Bonjovi is his nephew, and got his start sweeping the floor before Tony got him his first record contract]. I flew all over the US promoting Fairlight in my private plane for almost a year before anyone bought one. Remember, this was the first music sampler ever made, so it wasn’t as if people were automatically into it – the concept was entirely foreign at that stage. I remember taking it into Power Station with Bruce Springsteen and he said; “Ah yeah, BJ that’s great, but what am I gonna do with it?”.

Then out of the blue I got this phone call from Herbie Hancock, who said he knew this guy in California who would buy two. Later that same day I got a call from Stevie Wonder saying he really wanted to check it out. So I put the sampler in the back of the plane and took off for California. I flew solo for 15 hours, (only stopping for fuel and a pee), landed in Los Angeles and took the Fairlight straight over to Herbie’s house. Soon after, Geordie Hormel [self-styled singer songwriter and owner of The Village Recorder in LA] came by in his motor home and said that it was just what he’d been looking for, so he said: “I’ll take two”. And I said, “but they’re $27,500 each,” and he said “… I’ll take two.” At my next house call, Stevie Wonder bought one on the spot and signed a personal check with his thumb print. He then talked me into taking it out on tour with him on his Secret Life of Plants tour and before long Fairlight was finally up and running.

I remember one night [Elvis] was doing a show in front of 20,000 people and before I knew it he’d broken into a performance of Happy Birthday… for me

CAREER AVERAGE

AS: Your career is rare in that it seems to cover the live arena and the studio world in equal measure. How did you come to be so heavily involved in studio-based developments, or has that demarcation never existed in your mind?

BJ: My friend Bruce Brown, who built tape recorders and mixing consoles many years ago, was my inspiration in that world. Bruce is a great guy. He ran the studio at Alberts… forever. I always had a keen interest in the studio side of things but, of course, my expertise was in the live world. I was initially inspired by my disappointment in the sound of digital audio, but because I’d worked closely with the Fairlight I was well aware of its potential – and weaknesses: like noise and inharmonic distortion – that’s what inspired me to start up Apogee in my garage at home in Santa Monica.

AS: What aspects of digital equipment did you look to improve?

BJ: We just started with filters, the weaknesses of clocks, and we quickly established a patent on low-jitter clocks. The first design that got Apogee kicked off was a filter for the digital converters in Sony 3324, Otari and Mitsubishi digital tape machines. We figured if we sold a few thousand filters we’d be doing pretty well – in the end we sold 30,000, which was a great success.

While on tour in Japan with Springsteen, I was given one of the very first CD players. I went out and bought some CDs and it was all very exciting – but when I listened to it through the PA that night it was just horrible; my cassette sounded way better. It turned out that the Japanese had developed these textbook filters with extremely steep roll-offs, resulting in the phase being twisted around a couple of times at high frequency – it was way, way out. So we said, ‘do we really need these incredibly steep filters? What if we try and straighten out the phase.’ So we experimented and quickly discovered that you didn’t really need to protect for full amplitude signals at 20kHz because when you look at a regular mix, you’ve got a lot of energy down low, but it tapers off pretty heavily as you get up towards 20kHz. The filters we made had much gentler roll-offs and they were also linear phase. We also looked at a whole bunch of other things: intermodulation distortion, the choice of amplifiers, resistors and capacitors – we made a much better ‘mouse trap’ and the results were amazing.

Then we got together with a mathematician and started playing with ideas to make better dither and that ended up resulting in the UV22 algorithm. We realised that whatever aspect of a digital device we turned our attention to could be noticeably improved. It was great to have my own team of engineers to do whatever seemed like a good idea.

MYTHS AND SAMPLES

AS: What’s your feeling about the market’s current preoccupation with sample rate and bit depth specifications?

BJ: People will always be impressed by numerical improvements on specs sheets. For example, they’ll always say that 192k sampling rates are better than 96k sampling rates, when in reality there’s a whole bunch of other influencing factors responsible for any audible improvements. For instance, everyone talks about having these 24-bit converters, but right there is the biggest lie that ever was – no-one’s got a 24-bit converter! Converters have a dynamic range of around 6dB per bit, so 24-bit converters should theoretically have a dynamic range of 144dB. No-one has even come close to that in reality. They’re what I call ‘marketing’ bits. Those last few bits are certainly in the data you’re recording, but the real question is do they mean anything? And the answer is ‘no’ – they’re essentially meaningless. But we’re so brainwashed into thinking we’ve got to have 24-bit converters that now we’re loathe to buy anything else. Converters these days only have a maximum dynamic range of around 120dB – which equates to around 20 bits of meaningful data.

Another example of this is a listening test of audio sampled at 44.1k or 96k. The typical remark from listeners is that 96k sounds substantially better, and simplistically, this difference is inevitably attributed to the higher sampling rate, because it’s the only specification they can point to that has been substantially ‘improved’ (because the number is much larger!). My opinion is that, most of the time, what’s actually making things sound better in a converter is usually a number of other components that you never hear about. The fact is, well done 44.1k-sampled CDs played back on the right equipment can sound pretty amazing.

There are other areas where you can make a significant improvement in the digital chain. For instance, Dave McGrath at Lake has recently developed a radically improved Bi-Quad filter (which is something you use every time you touch a digital board’s EQ) by making some small changes, which have improved the low frequency noise and distortion problems significantly. These are where the real, audible improvements to digital technology are taking place.

INNOVATION

AS: What’s it like to be an innovator these days in a climate where so many ideas get ‘borrowed’ by other companies before you’ve had a chance to recoup your development costs?

BJ: First off, there are lots of people with lots of ideas but taking that idea and turning it into something tangible takes a lot of work. An idea itself is relatively cheap, but developing and manufacturing that idea into a saleable product these days takes a hell of a lot of effort and investment. For instance, the project I embarked on with David McGrath and Ed Meitner that resulted in the Clair I/O [otherwise know as the Lake Contour albeit with slightly different software] was bank-rolled by Clair Brothers in the US with my estimated development cost of around $800,000. Two million dollars (and then some) later we were still developing it. No one person could ever do it. You need a really strong team with expertise in all different areas of software and hardware.

Thankfully, all this technology we’ve built is very difficult to copy. There’s a limit to what people can emulate. What we’ve got in the Lake Contour and Mesa that’s creating these new ways of shaping EQ is state-of-the-art technology and not available in the technical literature. So I think it’s going to be a while before anyone’s able to copy our designs, other than superficially, perhaps.

AS: So, effectively, the cutting-edge nature of the designs doubles as a form of copyright protection?

BJ: Exactly. But having the technology doesn’t necessarily mean you’re going to capitalise on the mass market. To do that you have to have a totally different mindset. Unfortunately, in my career I’ve been driven by perfectionism, and try as I might, I find it very difficult to work any other way. But at some point you’ve just got to let go. I’m slowly getting better at it in the sense that I’m learning how to get more out of less these days. But I don’t think something’s worth doing unless you do it as well as you possibly can, that’s what gets me up in the morning; knowing that I’m doing the best I can, and always learning something new. You’ve got to surround yourself with the best people, keep learning and stay open-minded.

AS: Presumably that’s what you’ve achieved with David McGrath at Lake Technology. And given that Dolby has just bought the company I assumed they’d agree?

BJ: Surrounding yourself with the best people costs a lot of money. David McGrath co-founded Lake and has seen his share of company financial ups and downs… just as I did with Apogee. I really enjoy working with David and our team here at Lake. We feel really fortunate that Dolby recently took full control of Lake. They’re very excited about building their Lake division’s presence in the live sound, installation and studio worlds. We have a wealth of technology for in-ear monitoring, reverb and lots of other fun stuff and Dolby are right there with the backing to make it happen… much more than we could ever have achieved on our own. With the combined talents at Lake Technology and Dolby, there are exciting times ahead.

AS: Are you still flying?

BJ: Yeah, that’s my obsession. I’ve still got a little plane in a hanger in Santa Monica that I miss terribly. I’m thinking of flying it out here actually, which will be my next big adventure, but my wife’s not too keen on the idea.

RESPONSES